Working principle of air compressor

The air compressor is the main body of the air source device. It is a device that converts the mechanical energy of the prime mover into gas pressure energy. It is an air pressure generating device for compressed air. It is a machine that uses the principle of air compression to produce compressed air that exceeds atmospheric pressure.

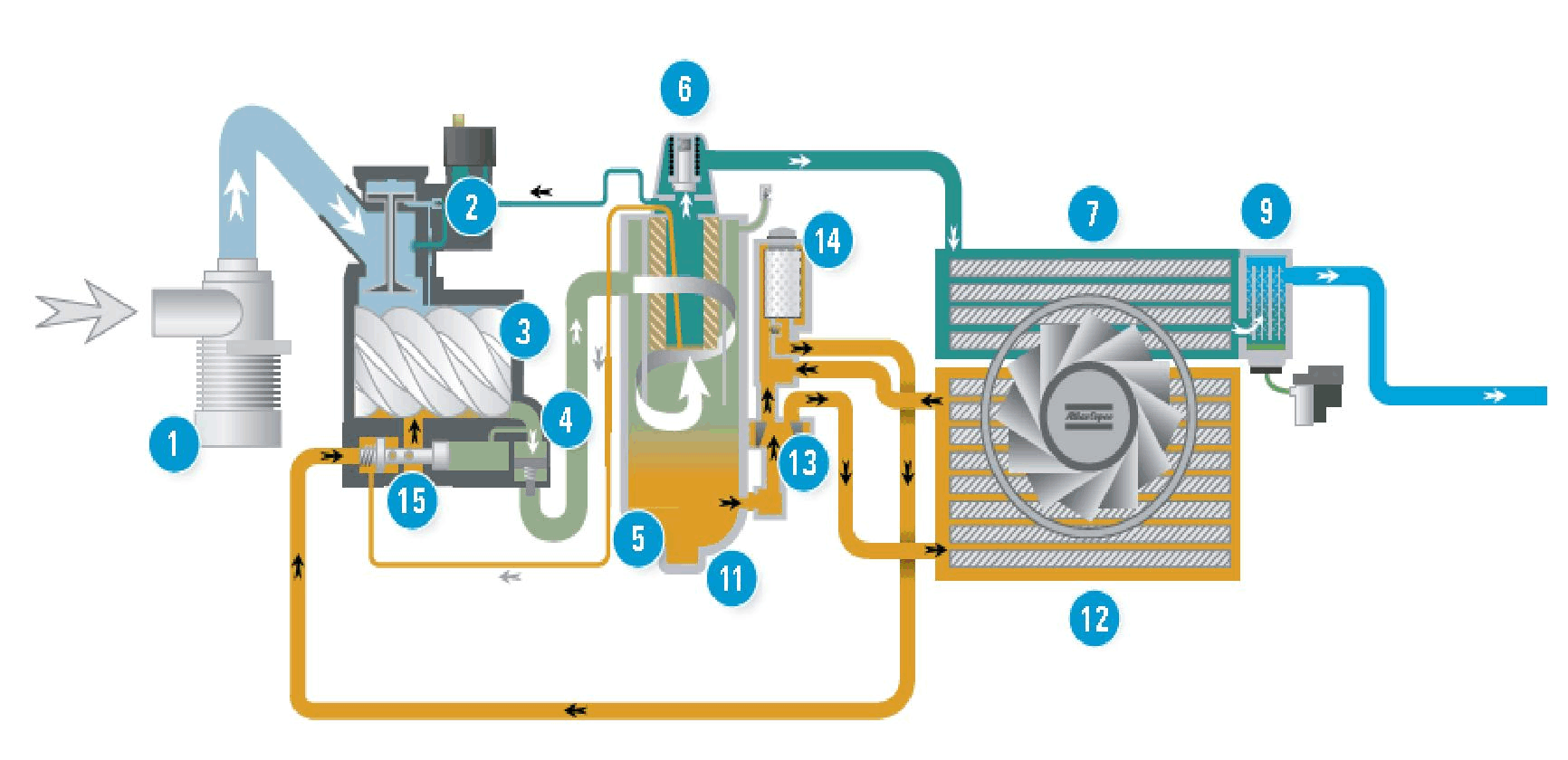

1. Principle of screw air compressor

The screw compressor is a positive displacement compressor with helical rotation, and it is one of the most widely used positive displacement compressors in the world.

In the body of the compressor, a pair of helical rotors meshing with each other are arranged in parallel. Usually, those with thicker teeth are called male rotors or male screws; those with thin teeth are called female rotors or female screws. Generally, the male rotor is connected to the prime mover, and the male rotor drives the female rotor to rotate. Ball bearings on the discharge end of the rotor allow the rotor to be positioned axially and withstand the axial forces in the compressor. At both ends of the compressor body, openings of a certain shape and size are respectively opened. One is for suction, called the suction orifice; the other is for exhaust, called the exhaust orifice. (Generally intake from the top, exhaust from the bottom).

The working cycle of the screw compressor can be divided into three processes: suction (1), compression (2) (3) and exhaust (4). As the rotor rotates, each pair of intermeshing teeth sequentially completes the same work cycle. The volume occupied by the gas sealed in the interdental volume decreases as the teeth move, resulting in an increase in pressure, thereby realizing the gas compression process. When the interdental volume is connected to the exhaust port, the exhaust starts. process.

Second, the principle of single screw air compressor

The working principle of the single-screw air compressor is through the alternating rotation of two star wheels, because their configuration is symmetrical, so that the space is divided into two, and each of them compresses the gas in it, and the balance force is symmetrical. The biggest feature of the screw machine is that the manufacturer has to solve the problem that the star wheel will wear too much at high speed and high temperature between the plastic star wheel and the screw, so as to ensure that the gas production will not drop too fast.

3. Principle of piston air compressor

The working principle of the piston air compressor is to use the crank connecting rod mechanism to convert the rotary motion of the prime mover into the linear reciprocating motion of the piston, and use the automatic opening and closing of the intake and exhaust valves to inhale, compress and discharge the gas. The method used is relatively backward, and the gas will contain a large amount of oil. This kind of equipment is not suitable for industries that require high precision of gas use. Secondly, there are problems of loud noise, gas pulses, and easy damage to the main engine.

Fourth, the principle of sliding vane compressor air compressor

Sliding vane compressors use conventional technology with direct drive at lower speeds. The rotor is a continuously running part with several grooves cut along its length, in which sliding vanes are inserted that can slide on the oil film.

The rotor rotates in the stator of the cylinder. During the rotation, centrifugal force throws the vanes out of the grooves to form individual compression chambers. The rotation makes the volume of the compression chambers decrease and the air pressure increases continuously. The oil is used to control the heat generated by the compression, which in turn completes the compression of the air.

Because the method used is relatively backward, the gas will contain a large amount of oil. At this time, the oil and gas separator is needed, and it can be put into production after filtering it clean. This kind of equipment is not suitable for high precision requirements for gas use. In the industry, there are also the problems of high noise and high maintenance cost of the main engine.

Five, the principle of centrifugal compressor

The working principle of the centrifugal compressor is that when the air enters the machine, the impeller in it will rotate rapidly, and the gas will then enter the diffuser and gradually complete the compression. Its most notable advantages are energy saving, large displacement, low failure rate, low operating cost, and oil-free compressed air, which is the first choice for users who consume more than 100 cubic meters of air.