Air Compressor Safety Operating Regulations

Air Compressor Safety Operating Regulations

1. General Provisions

1. The driver of the air compressor must pass the training, pass the examination, and obtain the certificate before being allowed to work.

2. The air compressor driver should be familiar with the general structure, working principle, technical characteristics, power supply system and control circuit of the air compressor.

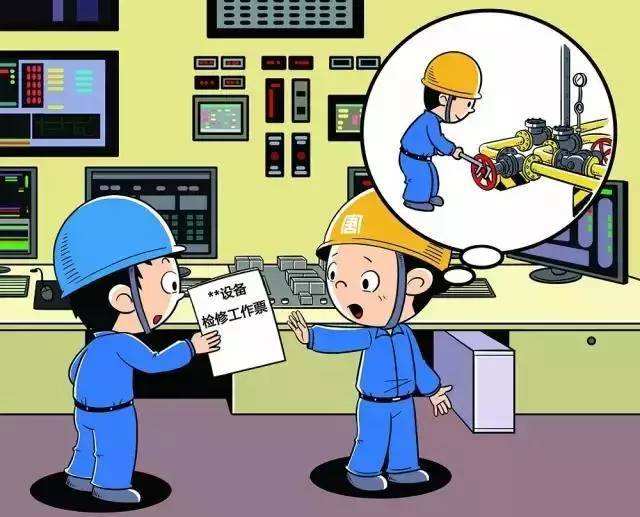

3. Air compressor drivers must strictly implement the "post responsibility system", "equipment handover system", "equipment tour inspection system", "equipment routine maintenance system" and other relevant system requirements.

2. Related operations

4. The air compressor driver should complete the following work:

(1) Ensure the normal operation of the air compressor.

(2) When the air compressor fails, take corresponding measures immediately and report to the dispatching room.

(3) Observe and inspect the operation of the air compressor, and make a record of the operation of the air compressor.

(4) Master the relevant provisions of the "Coal Mine Safety Regulations" on the management and start-up of air compressors.

(5) Master the knowledge of normal operation and daily maintenance of air compressors.

(6) Understand the mine gas supply system.

(7) Clean the machine room and equipment hygiene.

3. Safety regulations

1/6

5. The air compressor must be equipped with a pressure gauge and a safety valve, and operate reliably. The pressure gauge must be calibrated. Oil-lubricated air compressors must be equipped with an oil-cut protection device or an oil-cut signal display device. Water-cooled air compressors must be equipped with water-cut protection devices or water-cut signal display devices.

6. The exhaust temperature of the air compressor: the single cylinder shall not exceed 190 ℃, and the double cylinder shall not exceed 160 ℃. A temperature protection device must be installed to automatically cut off the power supply when the temperature is exceeded.

7. The suction port of the air compressor must be equipped with a filter device, and the air compressor oil must use compressor oil with a flash point of not lower than 215 °C.

8. The air bag with the air compressor should be installed in a cool outdoor place, and the temperature in the air bag should be kept below 120℃.

4. Operation preparation

9. The preparation and inspection before shipment requires:

(1) The fastening bolts are not loose.

(2) The tightness of the transmission belt is moderate and there is no breakage. Job-hopping and twisting phenomenon.

(3) The protective cover is installed firmly, and the electrical equipment is well grounded.

(4) The amount of grease in each lubricating oil cavity is appropriate, the oil passage is smooth, and the oil quality is clean.

(5) The cooling water is smooth, the water quantity is sufficient, the water quality is clean, and the water pressure meets the regulations.

(6) The over-temperature, over-pressure, oil-cut, and water-cut protection devices are sensitive and reliable.

(7) All indicating instruments are complete and reliable.

(8) The motor carbon brushes and slip rings are in good contact without jamming and burns (squirrel cages)

2/6

except type motors).

(9) The isolating switch and circuit breaker should be in the off position.

10. There is no jamming or abnormal noise when cranking.

5. Operation

11. Start the air compressor (the air compressor must start without load):

(1) Start (or operate) auxiliary facilities.

①Open the cooling water circuit and observe that there is sufficient water flowing through the return funnel.

②Open the gate valve on the exhaust pipe between the air compressor and the air storage tank.

③ Manually unload the unloader. If there is a pressure regulator, connect the three-way valve to the atmosphere to release the cylinder clearance.

④Put the lubricating oil into the cylinder, crosshead bearing and crankshaft bearing bush by hand cranking oil pump.

(2) Start the motor.

①After the synchronous motor is started asynchronously, when the acceleration reaches the rated asynchronous speed, the excitation is pulled into synchronization in time, and the co-magnetism can be adjusted to overexcitation to improve the power factor of the network, but the overexcitation current and voltage should conform to the working curve of the excitation device used.

②When the wound asynchronous motor is started with a rheostat, the handle of the motor slip ring should be in the "starting" position, and all the resistances should be put in before starting. Enter the normal speed, then turn the motor slip ring handle to the "run" position, and then return the starter handle to the "stop" position.

③ When the induction motor is started with a frequency sensitive resistor, the resistance must be thrown away after starting.

3/6

Lose.

④ When the asynchronous squirrel cage motor is started with reduced voltage, the "star-angle" conversion must be carried out after starting.

(3) When the air compressor reaches the normal pressure, the artificial unloading should be released immediately, the three-way valve should be cut off from the atmospheric passage, and the clearance valve should be closed.

12. After the normal operation of the air compressor, the driver should make a round inspection (usually once an hour). If abnormal phenomena are found, they should be reported and dealt with in a timely manner. The inspection tour is as follows:

(1) The temperature rise of each heating part shall be recorded in the operation log.

(2) Record the values of wind pressure, oil pressure, water pressure, voltage and current.

(3) The operation of the motor and air compressor.

(4) The working conditions of the oiler and the pressure regulator.

(5) The working conditions of the cooling system, oil supply system and exhaust system should be free from serious water leakage, oil leakage and air leakage, and the actions of various safety protection and automatic control devices should be sensitive and reliable.

13. The air compressor is shut down normally (it must be shut down without load):

(1) Stop steps:

① Artificial unloading.

②Stop motor operation.

③Release artificial unloading.

(2) After shutdown, the cooling water is turned off after the cylinder temperature drops to room temperature. If the ambient temperature is lower than 0°C, the cooling water remaining in the machine should be drained when the machine is shut down to prevent

4/6

Frozen equipment.

13. Air compressor emergency shutdown:

(1) When one of the following situations occurs, emergency shutdown should be made:

①The air compressor or motor has abnormal noise and vibration.

②The cooling water is abnormal, and the outlet water temperature exceeds the specification.

③ The motor emits smoke or fire or the motor ammeter indicates that the limit is exceeded.

④ When the oil pump pressure is not enough, the lubricating oil is interrupted or the pressure drops below 0.1 MPa.

⑤ The protection device and instrument are out of order.

⑥Other serious accidents

(2) Emergency shutdown shall be carried out according to the following procedures:

①If a fault occurs, it can be directly powered off and stopped (unloading and shutdown can be allowed under circumstances).

②When the machine stops automatically due to power failure, the power switch should be turned off.

Report the cement to the competent authority.

④When shutting down in winter, when the temperature of the cylinder drops below room temperature, turn off the cooling water and drain all the cooling water in the body at the same time.

16. Daily maintenance of air compressor drivers:

(1) Put the oil (water) in the air bag 1-2 times per shift.

(2) Test the safety valve and water cutoff protection (or cutoff signal) once per shift, and make a record.

(3) Test the oil pressure over-temperature protection device and pressure regulator once a week, and

5/6

Take good notes.

(4) Check the cylinder suction and exhaust valves every 100-150 hours of operation, and replace them if necessary.

16. Drivers should strictly abide by the following safety rules and operational disciplines:

(1) When operating high-voltage electrical appliances, one person is required to operate and monitor. Wear insulating gloves, insulating boots, and insulating pads when operating.

(2) The driver shall not arbitrarily change the setting value of the protection device.

(3) Operation is prohibited in the following cases:

①In the case of failure of the safety protection device, it is forbidden to start or run.

② In the case of poor grounding of the motor and electrical equipment, it is forbidden to start or run.

③It is forbidden to start or run when the indicator instrument is damaged and unsafe.

④ During the operation of the equipment, it is forbidden to fasten the anchor bolts.

⑤ When the cylinder and air bag are under pressure, knocking and collision are prohibited.

⑥) During the handling of the accident, the driver should strictly abide by the post, and are not allowed to leave the engine room.

6. Finishing work

17. Fill in and keep records truthfully.

18. Tools. Spare parts are neatly placed, and equipment and indoor and outdoor hygiene are well maintained